Clean compressed air is the requirement for quality and process reliability in many production processes and applications. The quality of the compressed air is determined by humidity, microbial count, oil concentration and solid particles.

An innovative process for separating the oil from the compressed air indicates new standards regarding process reliability, costs,condensate problems and environmental compatibility.

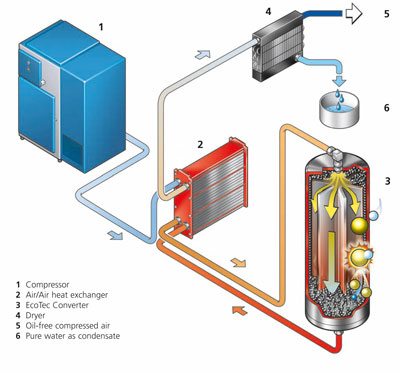

Previously oil was removed from compressed air by adsorption by active carbon. The EcoTec concept uses a special catalyst to convert the oil and other hydrocarbons in water and further harmless air components in a physical-chemical process (see left).

All oil molecules are burnt completely and effectively in the EcoTec Converter.The compressed air is absolutely oil-free and can be used without restrictions in all applications that require guaranteed oil-free compressed air.

The process is not only very ecological but also most economical as the service life is extremely long. The elimination of the disposal process results in enormous cost-savings potentials.

Chemical reaction in the EcoTec Converter ETC

Chemical reaction in the EcoTec Converter ETC

Installation Drawing

-

The EcoTec Converter is integrated into the compressed air network after the compressor(s) (1).

The compressed air flowing from the compressor is preheated in the Air/Air heat exchanger (2) and then flows into the converter (3) which is filled with granulate. An electrically operated heater maintains the converter at the operating temperature that is required to purify the compressed air.

While the air flows through the converter, the hydrocarbons it contains are catalytically oxidised.

The purified compressed air is then cooled down in the heat exchanger (2).After it has passed the EcoTec Converter, the quality of the compressed air (5) exceeds by far the requirements of ISO 8573-1 Class 1 for oil of 0.01 mg/m3.This highest standard is maintained throughout the complete service life of the converter.This means guaranteed process reliability!The condensate (6) from the dryer (4) is oil-free.

Your advantages using EcoTec converter

The combination of highly efficient oil-injected compressors with an EcoTec Converter results in the following unique advantages:

Guaranteed oil-free compressed air

Oil-free condensate at any time

Low energy consumption

Absolute operating reliability, because the degree of efficiency of the EcoTec Converter is independent of oil inlet concentration, inlet temperature, air humidity

Positive results in your environmental balance sheet

High economic efficiency and savings for your company

No maintenance problems

Complete elimination of the disposal problem and of all

the costs factors that this entails

EcoTec Converter ETC

The catalytic converter for absolutely oil-free compressed air

Oil-free compressed air in quality class 1 in accordance with ISO 8573-1 for

Breathing air Blowing air (PET) Food and Beverage industries Breweries Pharmaceutical industry Pneumatics Dairy Semiconductor industry Metal works Mechanical engineering Tobacco processing Textile industry

| KW |

Free Air Capacity |

Max Working Pressure |

Model |

| 1.2 |

1 |

16 |

ETC/1/7 |

| 5 |

2 |

16 |

ETC/S/2/7 |

| 5 |

4 |

16 |

ETC/S/4/7 |

| 5 |

7 |

16 |

ETC/S/7/7 |

| 7 |

10 |

16 |

ETC/S/10/7 |

| 10 |

15 |

16 |

ETC/S/15/7 |

| 14 |

20 |

16 |

ETC/S/20/7 |

| 18 |

25 |

16 |

ETC/S/25/7 |

| 28 |

40 |

16 |

ETC/S/40/7 |

| 28 |

50 |

|

16 |

ETC/S/50/7 |